Let’s be honest—when you hear “metaverse,” you might still picture clunky VR headsets and virtual real estate. But here’s the deal: the real action, the multi-trillion-dollar opportunity, isn’t in social hangouts. It’s on the factory floor, inside power plants, and across global supply chains. This is the industrial metaverse, and its most powerful tool is the digital twin.

Think of it this way. For decades, we’ve built things, tested them, and hoped for the best. It’s a bit like baking a complex cake for the first time and only discovering you’re out of sugar after you’ve already put it in the oven. Frustrating, wasteful, and expensive. Digital twin technology changes that entire recipe. It gives you a perfect, virtual copy of that cake—the ingredients, the oven’s heat flow, everything—so you can simulate, tweak, and perfect the process before you ever crack a real egg.

What Exactly Are We Talking About? Cutting Through the Jargon

Okay, so let’s define our terms, but in plain English. A digital twin is a dynamic, data-driven virtual model of a physical object, process, or system. It’s not just a 3D CAD drawing. It’s a living replica that learns, updates, and mimics its real-world counterpart using data from sensors, IoT devices, and operational history.

The industrial metaverse is the immersive, interconnected space where these digital twins live, interact, and are used by people. It’s the shared platform where an engineer in Berlin can collaborate in real-time with a maintenance crew in Texas, all interacting with a virtual model of a turbine as if they were standing right next to it. It blends AR, VR, AI, and cloud computing into a single, powerful environment for industry.

The Tangible Payoff: Where Investments Are Paying Off Now

This isn’t speculative future-tech. Companies are seeing staggering ROIs today. The investment case isn’t about being trendy; it’s about solving massive, costly pain points.

1. Supercharged Product Development & Innovation

Imagine testing a new aircraft engine design under extreme stress for thousands of virtual hours. Or simulating how a new car’s chassis handles a pothole in Mumbai’s monsoon. You can do all that—faster, cheaper, and without physical risk. This accelerates time-to-market dramatically while slashing prototyping costs. It’s a no-brainer for R&D-heavy sectors.

2. Predictive Maintenance That Actually Works

This is a huge one. Instead of following a rigid maintenance schedule (or worse, waiting for something to break), digital twins predict failures before they happen. The twin analyzes real-time sensor data—vibration, temperature, pressure—and flags anomalies. You fix a pump on Tuesday because the model says it will fail Friday. You avoid a $2 million production line shutdown. That’s the kind of concrete value that gets CFOs excited.

3. Revolutionizing Training and Workforce Skills

Training a technician to service a million-dollar MRI machine is risky. But in the industrial metaverse? They can practice complex procedures dozens of times in a risk-free, virtual environment. It bridges the skills gap faster and safer. New hires get up to speed, and seasoned experts can simulate rare, complex scenarios.

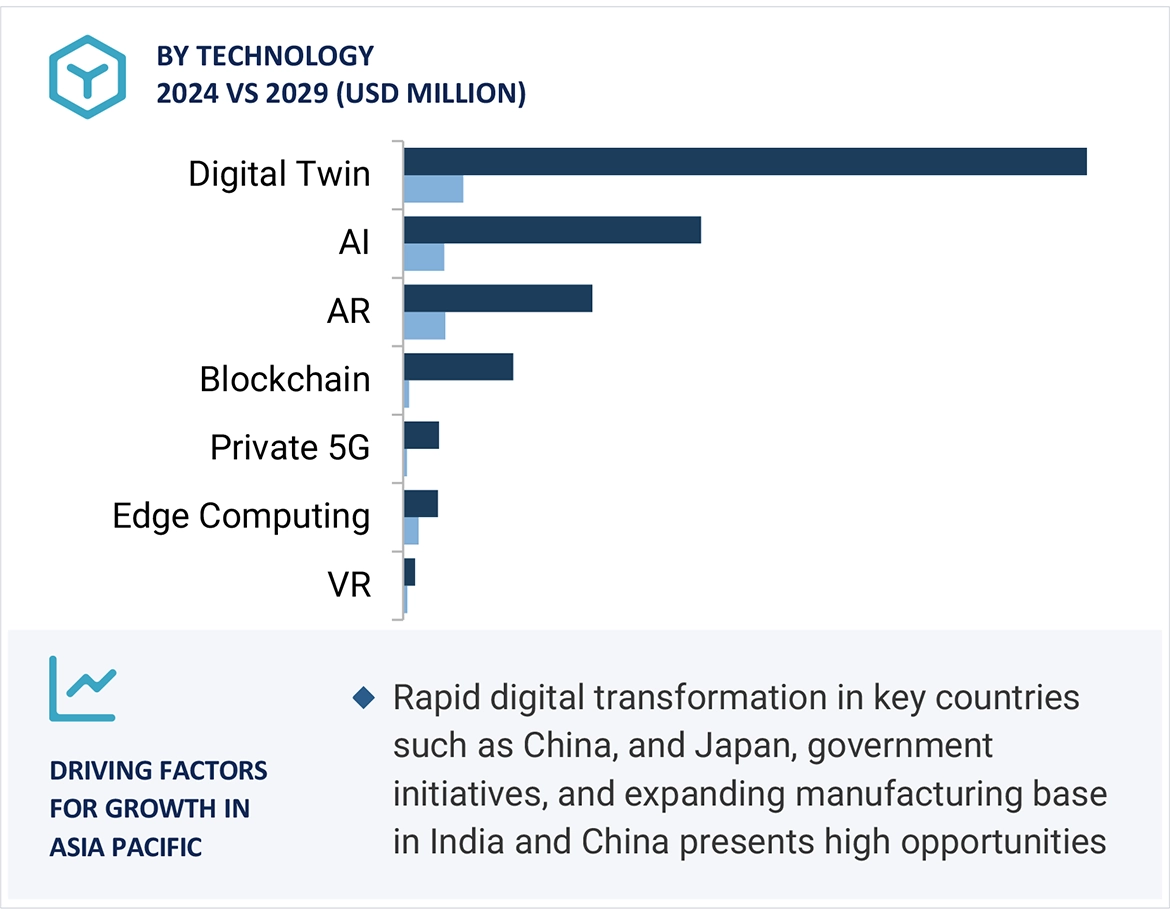

The Investment Landscape: Where to Place Your Bets

So, you’re convinced of the potential. But where does the smart money go? The ecosystem is broad, but a few key areas stand out.

| Investment Focus Area | What It Enables | Real-World Example |

| Platform & Infrastructure | The foundational software and cloud systems that host and synchronize digital twins. | Companies building the “operating system” for the industrial metaverse. |

| Data Integration & AI | The tools that pull data from siloed sources (ERP, SCADA, IoT) and make the twins intelligent. | AI firms specializing in predictive analytics for physical assets. |

| Sensors & Connectivity (IoT) | The physical hardware that feeds real-time data to the virtual model. | Advanced sensor manufacturers and 5G/private network providers. |

| Specialist Applications | Vertical-specific solutions for manufacturing, energy, smart cities, etc. | A startup creating digital twins for optimizing wind farm layouts. |

Honestly, the platform players might seem like the obvious choice—they’re the pickaxes in this gold rush. But the specialist applications solving niche, high-value problems can offer explosive growth. It’s about finding where deep industry knowledge meets cutting-edge tech.

Not All Sunshine: The Challenges You Can’t Ignore

Look, it’s not a plug-and-play paradise. The path is littered with hurdles. Data silos are the arch-nemesis. If your production data can’t talk to your supply chain data, your twin is blind in one eye. Then there’s the skills gap. You need “bilingual” teams who understand both the physical industrial processes and the digital tools.

And let’s not forget security. Creating a perfect digital replica of your entire operation is… well, it’s a supremely attractive target for bad actors. Cybersecurity isn’t an add-on here; it’s the bedrock.

The Human in the Loop: Where We Really Win

Here’s a crucial point that gets lost sometimes. This tech isn’t about replacing people. It’s about augmenting human intelligence. The industrial metaverse, at its best, is a collaboration space. It takes the intuition, experience, and problem-solving skills of a veteran engineer and supercharges them with perfect information and simulation superpowers.

It allows for better, faster decisions. Should we reconfigure the assembly line? Run the twin. What if this pipeline corrodes here? Simulate it. The technology handles the complex data-crunching, freeing up humans for the creative, strategic work that machines can’t do.

A Future, Built Twice

In the end, investing in the industrial metaverse and digital twin technologies is a bet on a fundamental shift in how we build and manage the physical world. We’re moving from a paradigm of “build, break, fix” to one of “simulate, optimize, build.” It means constructing everything—from products to cities—first in a virtual space where failure is a free lesson, not a catastrophic cost.

The companies that master this duality, that learn to navigate seamlessly between the digital and physical, won’t just be more efficient. They’ll be more resilient, more innovative, and frankly, more in tune with a world that is, for better or worse, being digitally mirrored all around us. The future, it seems, will be built twice. The question is, who will be holding the blueprint?